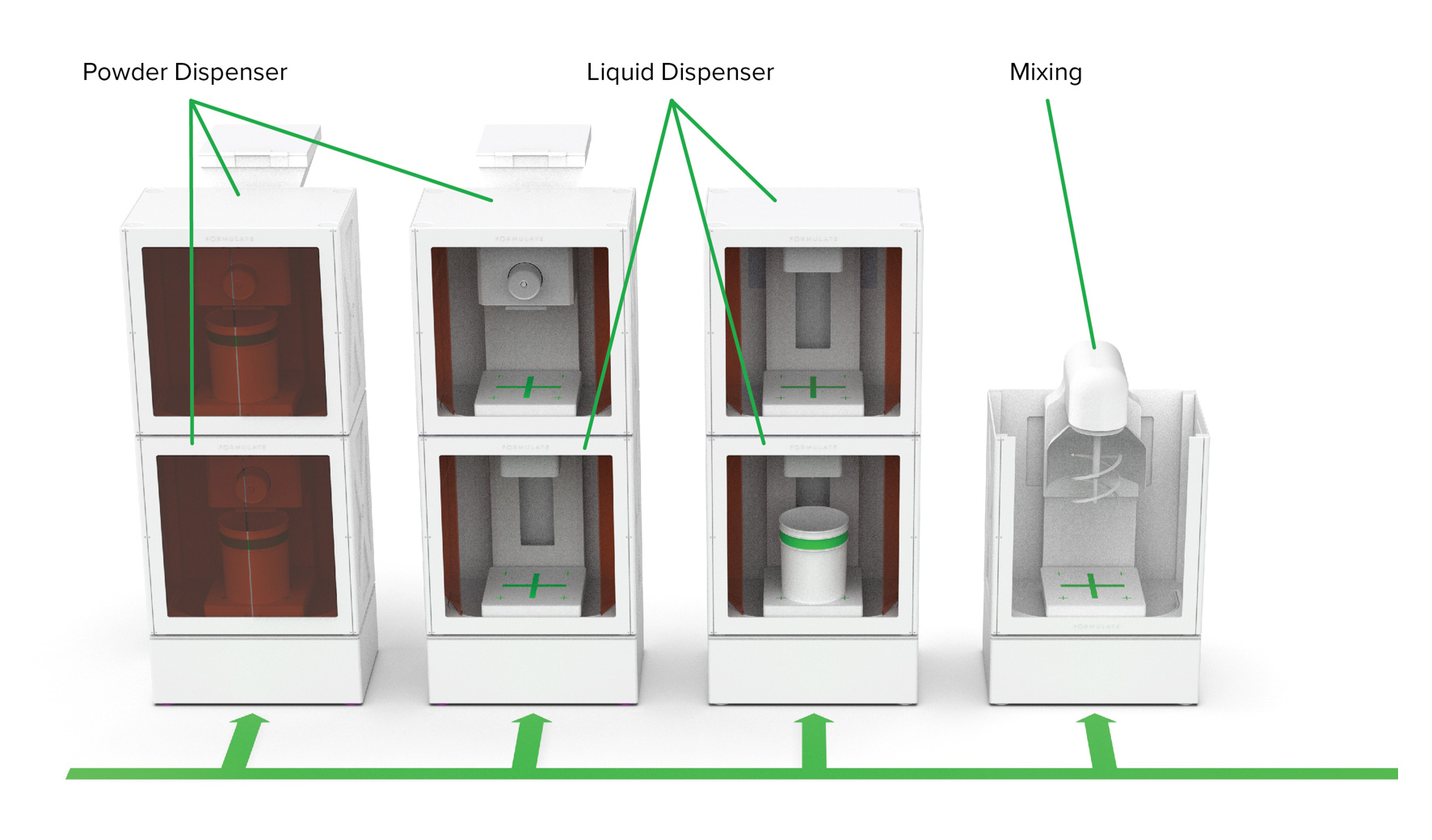

Building the robotic kitchen for chemistry-driven products

What AWS did for compute, we're doing for physical production of personal care, oral care, health & wellness, supplements, pet care, pharmaceuticals, household products, fragrances, flavors, and specialty chemicals.

API/Software Powered

Control production like code, from anywhere

Touchless, Plug-n-Play

Set up in under a day, with <1 hour of training. Just load materials and go.

Less Waste, Labor, Energy

Save up to 90% on scrap & waste. Cut energy use by 50% closed-loop automation.